GAM386 Automatic PCB Router Machine

Suitable for PCB the high components on its top.

Equipped with high-speed CCD vision alignment system.

Use auto tool-change spindle to save manual tool-change time costs.

Provide dual worktables and also can be merged to form a single worktable.

Software and hardware with a number of optional features.

Can choose lower dust collector.

| GAM386 | |

|---|---|

| Valid cutting size | 300*350 mm |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc |

| Process precision | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XYZ: 1000mm/sec Z: 500mm/sec |

| Max moving trip | X:700mm Y:380mm Z:90mm |

| Spindle's speed | MAX: 60000rpm |

| Tool change type | Auto tool change |

| Milling tool detection | Automatic router bit detector |

| Cutting speed | 1-100mm/s |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | ∮0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60HZ 2.2KW 1Φ |

| Pneumatic pressure requirement | 0.6MPa,50L/min |

| Dimensions(W*D*H) | 1511*912*1462mm |

| Weight | 340KG |

| Dust collector | TS300 |

| Change without notice. Welcome customized request. |

|

- barcode reader

- Milling tool diameter detection

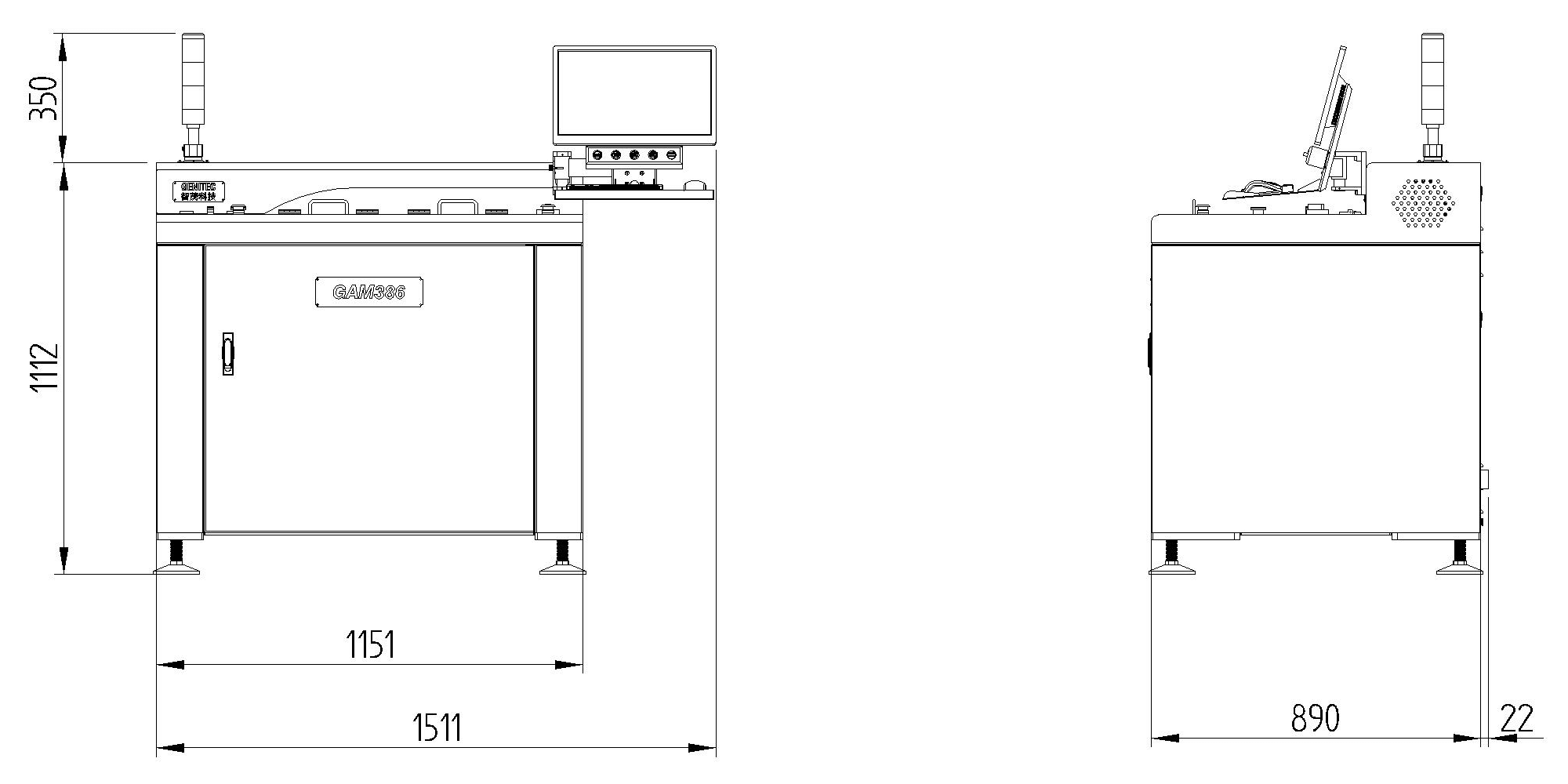

Front View/Side View

| GAM386 | |

|---|---|

| Valid cutting size | 300*350 mm |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc |

| Process precision | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XYZ: 1000mm/sec Z: 500mm/sec |

| Max moving trip | X:700mm Y:380mm Z:90mm |

| Spindle's speed | MAX: 60000rpm |

| Tool change type | Auto tool change |

| Milling tool detection | Automatic router bit detector |

| Cutting speed | 1-100mm/s |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | ∮0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60HZ 2.2KW 1Φ |

| Pneumatic pressure requirement | 0.6MPa,50L/min |

| Dimensions(W*D*H) | 1511*912*1462mm |

| Weight | 340KG |

| Dust collector | TS300 |

| Change without notice. Welcome customized request. |

|